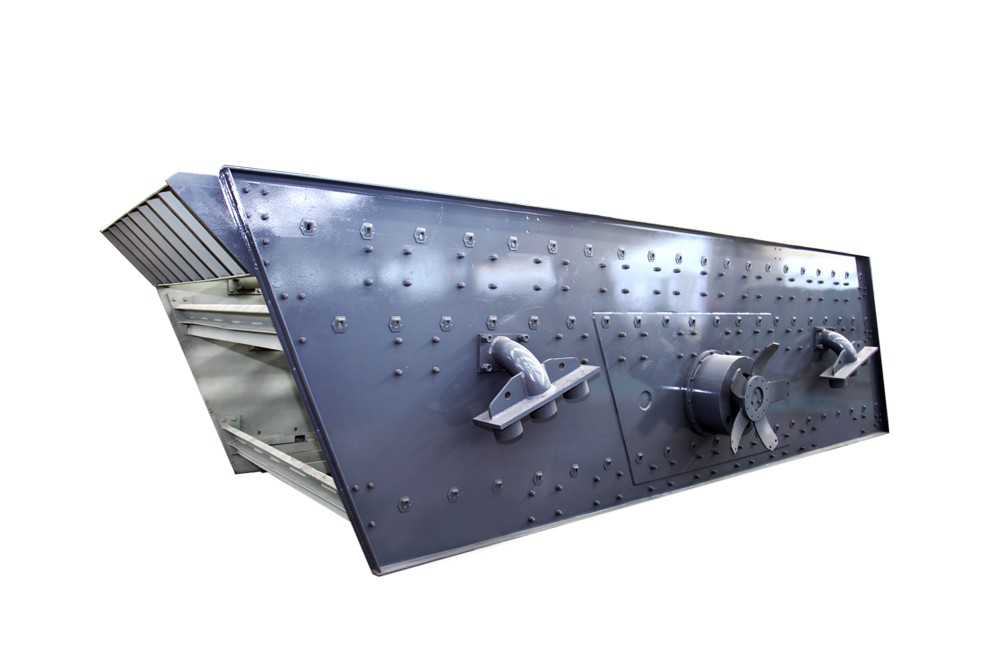

SBM YKN series circular vibrating screen is a high-efficiency circular vibrating screen with high strength and large exciting force. YKN series circular vibrating screen adopts N series block eccentric vibration exciter, and the intermediate transmission connection adopts flexible connection, so that the amplitude becomes larger and the vibration is constant; The passing capacity and screening efficiency are enhanced, ensuring more reliable operation of vibrating screen, and realize longer service life.

Classical Structural Design, Simple &Convenient Installation

YKN inherits classical structural design of traditional vibrating screens, and the whole structure is simple so the installation, adjustment, parts replacement and maintenance become simple and convenient.

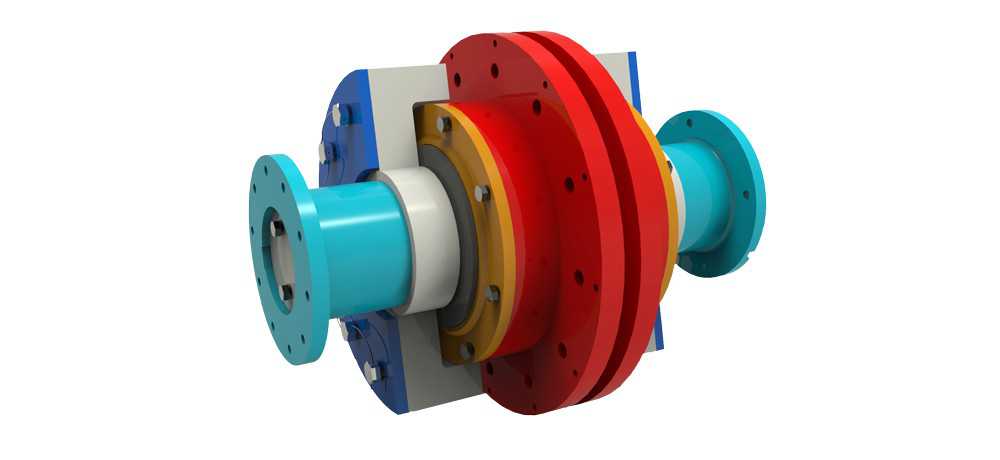

Unique Vibration Exciter Design, Stronger Exciting Force and Simpler Adjustment

Compared with the axis eccentric vibration exciter, the external block eccentric vibration exciter used by YKN series circular vibrating screen has stronger exciting force. In addition, this design can also easily adjust the amplitude and frequency of vibrating screen, so as to satisfy different using requirements.

Better Transmission Design and More Stable Operation

During the actual using process, we found that strong body vibration would generate during the starting and stopping processes of traditional circular vibrating screen, which seriously affects the service lives of motor and belt. Therefore, in the design of YKN series circular vibrating screen, we adopt advanced V-belt fitted with flexible connection technology, which will not transmit the axial force when the moment transmits, thus making screen operation more stable.

Finite Element Analysis Technology and Advanced Processing Technology, Guaranteeing the Structural Strength

In the design of YKN series circular vibrating screen, we adopt finite element analysis technology to optimize the calculation of screening box, so as to make the load-carrying situations of the whole screening box and side plate more reasonable; in addition, for the processing of side plates, we use large-scale machine tool to directly bend the plate, which effectively avoids the risk of cracking caused by welding.

| Model | Capacity(t/h) | Power (kw) |

| 2YKN2160 | 100~600 | 30 |

| 3YKN2160 | 100~600 | 37 |

| 4YKN2160 | 100~600 | 45 |

| 2YKN2460 | 150~850 | 30 |

| 3YKN2460 | 150~850 | 37 |

| 4YKN2460 | 150~850 | 45 |